The L298N Motor Driver Module is a cornerstone component for controlling DC motors and stepper motors in DIY robotics and electronics projects. In this guide, we’ll explore everything you need to know—from pin configuration to real-world applications and how it compares to modern alternatives like L293D, DRV8833, and TB6612FNG.

🔍 What is the L298N Motor Driver Module?

Contents

- 1 🔍 What is the L298N Motor Driver Module?

- 2 ⚙️ Features of the L298N Motor Driver

- 3 🧠 Understanding How L298N Works

- 4 📌 L298N Module Pinout

- 5 🔌 Circuit Diagram

- 6 🛠️ How to Connect and Use L298N with Arduino

- 7 📦 Applications of L298N

- 8 🔄 Comparison: L298N vs Other Motor Drivers

- 9 📈 Pros and Cons of L298N

- 10 🤖 Ideal Use Cases for L298N

- 11 ❓ Frequently Asked Questions (FAQs)

- 12 📝 Conclusion

The L298N module is a dual H-Bridge motor driver that allows you to control the speed and direction of two DC motors or one stepper motor. It is based on the L298N IC, a 15-pin high-voltage, high-current dual full-bridge driver designed to drive inductive loads.

It’s widely used in:

- DIY Robots

- Line-following Cars

- Automated Vehicles

- Smart Cars and Arduino Projects

⚙️ Features of the L298N Motor Driver

| Feature | Specification |

|---|---|

| Operating Voltage | 5V to 35V |

| Logic Voltage | 5V |

| Max Current per Channel | 2A |

| Total Power Dissipation | 25W (with heat sink) |

| Motor Channels | 2 (can drive 2 DC or 1 stepper) |

| Built-in Diodes | Yes (for back EMF protection) |

| PWM Control | Yes |

| Heat Sink | Yes |

🧠 Understanding How L298N Works

The L298N uses H-Bridge logic to control motor direction. An H-Bridge is a circuit that enables a voltage to be applied across a load in either direction.

- IN1 & IN2 control Motor A

- IN3 & IN4 control Motor B

- EN_A and EN_B are used for speed control (can connect to PWM pins of Arduino)

Working Principle:

- IN1 HIGH & IN2 LOW → Motor A rotates forward

- IN1 LOW & IN2 HIGH → Motor A rotates backward

- ENA PWM signal → controls motor speed using Arduino

analogWrite()function

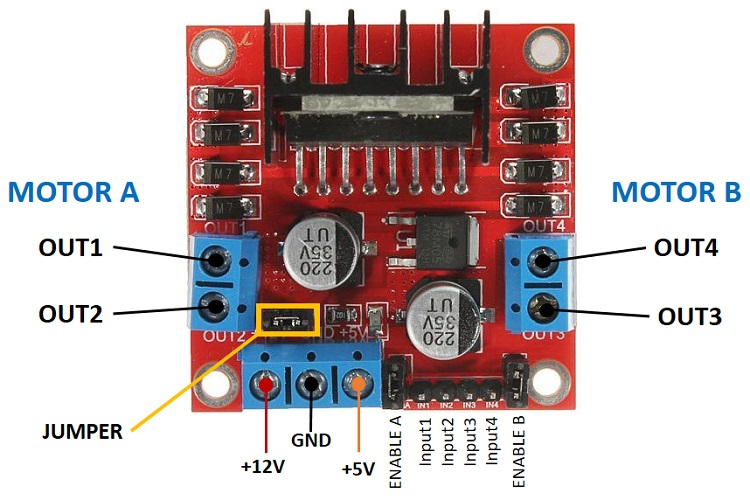

📌 L298N Module Pinout

Here’s a simple breakdown of the pins:

| Pin Name | Function |

|---|---|

| IN1, IN2 | Motor A Direction Control |

| IN3, IN4 | Motor B Direction Control |

| ENA, ENB | Enable Pins (Speed via PWM) |

| OUT1, OUT2 | Motor A Output |

| OUT3, OUT4 | Motor B Output |

| VCC | Motor Voltage (up to 35V) |

| GND | Ground |

| 5V | Logic Supply (internal regulator if jumper used) |

🔌 Circuit Diagram

Simple Arduino + L298N + 2 DC Motors Circuit:

rustCopyEditArduino -> L298N

---------------------------

D9 -> ENA

D8 -> IN1

D7 -> IN2

D6 -> IN3

D5 -> IN4

D3 -> ENB

+12V Battery -> VCC

GND -> GND

🛠️ How to Connect and Use L298N with Arduino

Required Components:

- L298N Module

- Arduino Uno/Nano

- Jumper wires

- DC Motors

- Power Supply (12V battery or adapter)

Code Example:

cppCopyEditint in1 = 8;

int in2 = 7;

int ena = 9;

void setup() {

pinMode(in1, OUTPUT);

pinMode(in2, OUTPUT);

pinMode(ena, OUTPUT);

}

void loop() {

digitalWrite(in1, HIGH);

digitalWrite(in2, LOW);

analogWrite(ena, 200); // Speed control (0-255)

delay(2000);

digitalWrite(in1, LOW);

digitalWrite(in2, HIGH);

analogWrite(ena, 200);

delay(2000);

}

📦 Applications of L298N

- Line Following Robots

- Obstacle Avoidance Cars

- Automated Vehicles

- DIY Arduino Cars

- CNC Machines (low power)

- Smart Home Projects

🔄 Comparison: L298N vs Other Motor Drivers

Let’s compare the L298N with popular alternatives to see where it stands:

1. L298N vs L293D

| Feature | L298N | L293D |

|---|---|---|

| Max Current | 2A per channel | 600mA per channel |

| Voltage Range | 5V–35V | 4.5V–36V |

| Heat Sink | Yes | No |

| PWM Supported | Yes | Yes |

| Back EMF Diodes | Built-in | Built-in |

| Size | Larger | Compact |

| Cost | Affordable | Cheaper |

Verdict: L298N is better for high current motors; L293D for smaller projects.

2. L298N vs TB6612FNG

| Feature | L298N | TB6612FNG |

|---|---|---|

| Max Current | 2A | 1.2A (3.2A peak) |

| Efficiency | Low (more heat) | High |

| Voltage Drop | ~2V | ~0.5V |

| Size | Larger | Compact |

| Heat Sink | Required | Not required |

Verdict: TB6612FNG is more efficient and better suited for battery-powered projects.

3. L298N vs DRV8833

| Feature | L298N | DRV8833 |

|---|---|---|

| Voltage Range | 5V–35V | 2.7V–10.8V |

| Max Current | 2A | 1.5A |

| PWM | Yes | Yes |

| Size | Larger | Compact |

| Efficiency | Low | High |

Verdict: DRV8833 is more suitable for low-voltage applications with better efficiency.

📈 Pros and Cons of L298N

✅ Pros:

- Easy to use with Arduino

- Can control two motors independently

- Integrated heat sink

- Can power motors up to 35V

- Built-in diodes for protection

❌ Cons:

- Large voltage drop (not energy efficient)

- Bulky size

- Generates heat (requires heat sink)

- Less efficient than modern ICs

🤖 Ideal Use Cases for L298N

- School and college robotics projects

- Beginner-level Arduino motor control

- Budget DIY electronics

- Projects with external power supply (not battery-based)

❓ Frequently Asked Questions (FAQs)

Q1: Can L298N drive stepper motors?

Yes, it can drive unipolar and bipolar stepper motors by controlling multiple pins.

Q2: Does it support PWM speed control?

Yes, ENA and ENB pins support PWM input to vary motor speed.

Q3: Is L298N suitable for battery-powered robots?

Not ideal. Due to high voltage drop and heat dissipation, it’s not battery-efficient. Use TB6612FNG or DRV8833 instead.

Q4: How much current can it handle?

Up to 2A per channel with a proper heat sink. Avoid pushing to the limit continuously.

Q5: Can I power the Arduino from L298N?

Only if using a 12V supply and removing the 5V jumper. But it’s safer to power Arduino separately.

📝 Conclusion

The L298N Motor Driver Module is a reliable and affordable solution for controlling motors in beginner to intermediate DIY projects. Though not the most efficient or compact, its robustness and ease of integration with Arduino make it a go-to choice for many hobbyists.

However, for advanced or battery-powered applications, modern alternatives like TB6612FNG or DRV8833 are recommended due to higher efficiency and compact size.